- FINE BUBBLE DIFFUSER

HOME FINE BUBBLE DIFFUSER

FINE BUBBLE DIFFUSER

Fine bubble diffusers produce oxygen bubbles to nourish microorganisms during the wastewater treatment aeration process. Aeration, the biological process that occurs during the secondary phase of wastewater treatment, relies on quality bubble diffusers to supply oxygen to the beneficial bacteria that break down organic matter.

Fine bubble diffuser systems save energy by producing efficient aeration and oxygen transfer. A wastewater treatment system’s Standard Aeration Efficiency (SAE) is the amount of oxygen the blowers diffuse into wastewater per horsepower hour. Fine bubble diffusers can produce over twice as much oxygen mass with half as much air as coarse diffusers.

Waste Water Aeration

JetFlex® diffuser elements for activated sludge plants

Jäger Umwelt-Technik has been developing and producing fine-bubble diffuser elements with high-performance membranes made of EPDM, silicone and PU since the early 1980s. Today, Jäger Umwelt-Technik aeration systems contribute to the treatment of municipal and industrial wastewater worldwide. Our systems make an essential technological contribution to the long-term undercutting of the legally prescribed effluent values and this with the lowest possible energy consumption. Environmental protection already begins in our production. With shortened internal supply routes, energy-saving manufacturing concepts and the increasing use of recycled and recyclable materials, we are already continuously reducing the carbon footprint of our products.

JetFlex® HD Disc Diffuser (HD-Series)

An important element in biological treatment plants is the aeration system. The JetFlex® HD disc diffuser series is a fine-bubble aeration system operated by compressed air. It is used worldwide in municipal and industrial wastewater treatment plants.

Our disc aerators combine low design, installation and maintenance costs with reliability, durability and efficiency – for intermittent and continuous aeration. The disc aerators can be equipped with an optional check valve that prevents backflow of sludge water into the pipeline even if the diaphragm is defective. To increase the efficiency of existing aeration systems, we also offer retrofit kits and exchange membranes.

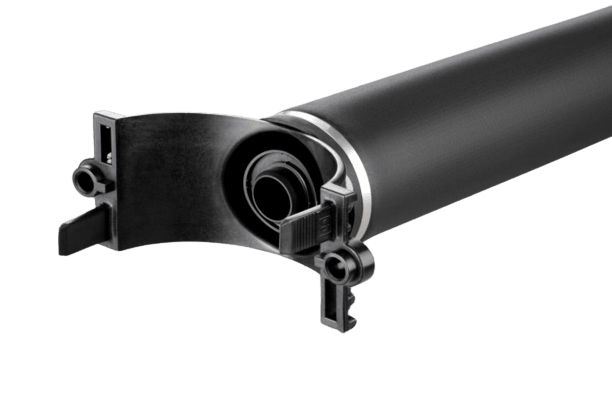

JetFlex® TD Tube Diffuser (TD Series)

The JetFlex® TD series of tube air diffuser is a fine bubble aeration system that uses compressed air. Our tube diffuser combine cost-effective design, low installation and maintenance costs with reliability, durability and efficiency. They are suitable for both intermittent and continuous operation. We also offer replacement membranes to increase efficiency in existing aeration systems.

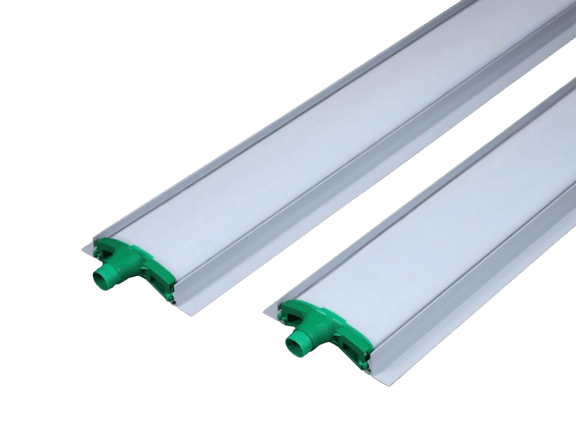

Jetflex® SSD: The Smart Strip Diffuser

the membrane is designed as a continuous airtight double membrane and is fitted with an air connection. The air introduced between the membranes can only escape via the microperforation of the upper membrane. As a result, the membrane is completely decoupled from the base structure — a feature unique to this diffuser type.

If only the membrane is to be supplied, it can be rolled up in a spiral form. This drastically reduces shipping weight and volume.

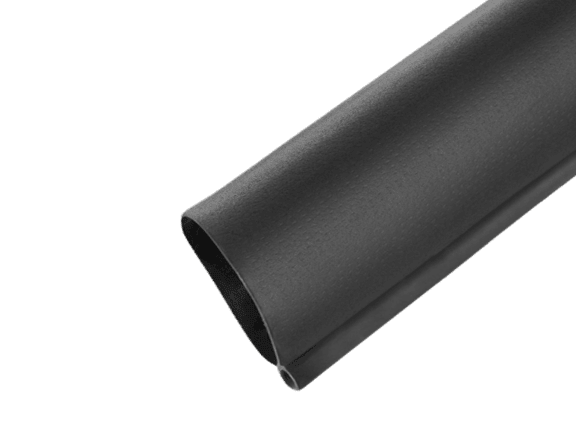

Jetflex® ENDLESS TUBE DIFFUSER

The Endless Tube 75 provides a solution for efficient aeration system without conventional piping requirement and the possibility of high local contents. The ET75 offers the advantages of saving in terms of cost and installation time. Basic accessories are needed for an easy and fast installation. These can be purchased separately from local sources or can be ordered completely from Jäger Umwelt-Technik (JUT). Based on different tank dimensions, we design with different lengths of diffusers for each project. In addition to that, the layout of the system in the tank will be prepared and made available to you. In this way, you can benefit from uniform diffuser distribution and achieve optimum aeration efficiency with easy installation and lower total costs.

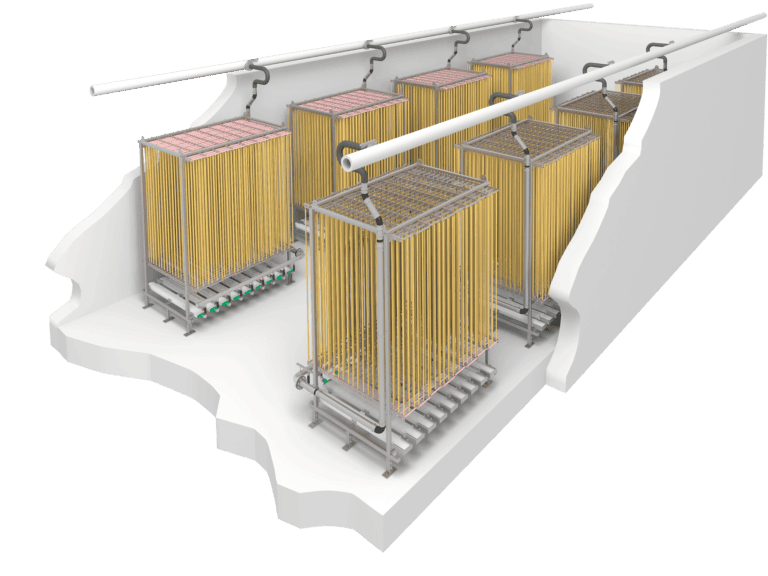

Cleartec® BioCurlz

Cleartec® offers an attached growth media in the shape of a synthetic textile which is waste water resistant. The material is either Polypropylen (PP) – Biotextile or a combination of PP and Saran (PVdC) – BioCurlz. In order to keep the media in the system, the textile is fixed to e.g. a Stainless Steel module. Nevertheless the media is able to move due to the textile nature. The increased biomass produced by the curl-like textile enables biological wastewater treatment on a small surface area.

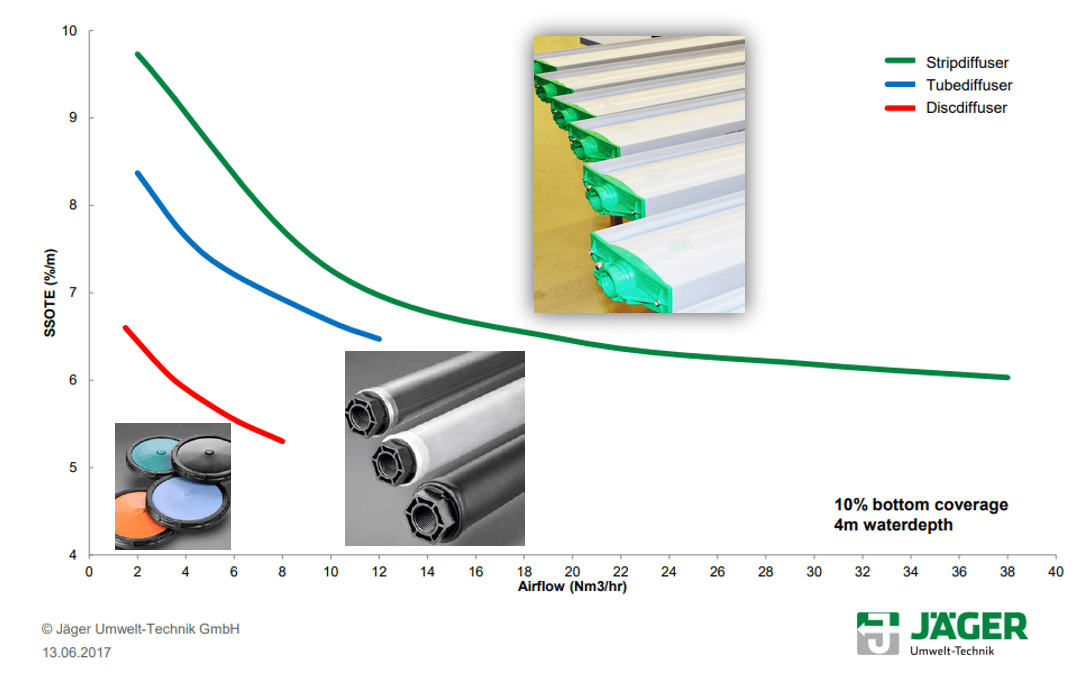

standard oxygen transfer efficiency